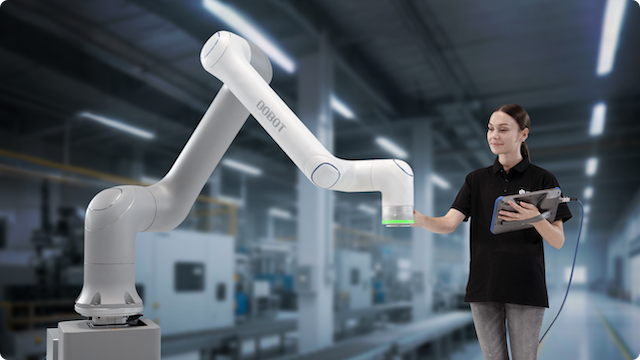

DOBOT CR‑30H

DOBOT CR‑30H

CR‑30H Heavy‑Payload

Il cobot 30 kg più veloce della categoria: fino a 300°/s sui giunti, ripetibilità ±0,05 mm, opzioni NSF/IP65 e HyperMove™ per +20% efficienza.

Varianti

CR 30H - Standard

Reliable Performance, Unmatched Productivity

2× throughput capacity versus conventional systems, unleashing full-scenario productivity.

CR 30HT - Touch

Intuitive Collaboration, Effortless Teaching

Built-in joint torque sensors for one-hand drag-to-teach and instant collision detection.

CR 30H‑Food - Clean

Food-Safe Automation Certified

NSF-certified components, food-grade lubricants and hygienic smooth-surface design.

High Speed

Palletizing Power Unleashed, Productivity Doubled

Smarter Speed, Proven Results: Equipped with HyperMove™ motion control that intelligently adjusts acceleration to maintain maximum reliable speed, delivering 20% higher single-unit efficiency than competitors.

Palletizing/Handling Pace: 10 pcs/min: Unlike the traditional palletizing system, the CR 30H solution can achieve new levels of automated palletizing performanc.

High Stability

at Full Speed & Load < 0.3mm vibration amplitude

Advanced Vibration Suppression Algorithm: Effectively reduces vibrations and end-effector oscillations across the full speed and payload range.

High-Density Servo Drive Technology: 96V mid-voltage servo drive delivering 50% more power with 20% less heat generation.

Optimized Joint Stability: 30% fewer components and optimized load distribution reduce stress on parts and cut downtime by 45%.

Fail-Safe Electromagnetic Braking: Brakes automatically engage during power loss, limiting end-effector displacement to <1mm.

IP67 Rugged Protection: Resists dust, water jets, and oil contamination.

Smarter

Smoother and More Efficient Operation

One-hand Drag-to-Teach: The industry's first 30kg-payload cobot with built-in torque sensors, improving teaching efficiency by 90%.

Ultra-Fast Control Cycle: 1kHz real-time control frequency minimizes command latency, enabling high-speed motion without overshooting.

Specifiche CR 30H

- Velocità giunti

- J1/J2 150°/s, J3 200°/s, J4/J5/J6 300°/s

- End‑I/O

- 0/12/24V, 2A avg, 3A max · DI 4 · DO 4 · RS485 1

- Comunicazione

- Ethernet (TCP/IP, Modbus TCP, Ethernet/IP, PROFINET); RS485 (Modbus RTU); USB

- Grado di Protezione

- Robot IP67 · Control cabinet IP20 (IP54 opzionale)

- Rumore

- 70 dB(A)

- Temperatura

- 0–50 °C

- Montaggio

- Pavimento / Parete / Soffitto

Applicazioni Heavy‑Duty

Pallettizzazione veloce (fino a 10 pz/min), handling, saldatura e machine tending in ambienti intensivi.

Automotive

Saldatura TIG/MIG/spot, assemblaggio moduli pesanti.

Metal Processing

Movimentazione e lavorazioni su pezzi di grandi dimensioni.

Semiconductor

Handling preciso con ripetibilità ±0,05 mm.

Food & Beverage

Versione Clean con componenti certificati NSF.

Serve aiuto per CR‑30H?

Ti supportiamo nella definizione della soluzione heavy-duty più adatta: efficacia, sicurezza e integrazione.

Parla con un Esperto